In the oil and gas industry, accurate inspection and calibration of storage tanks are crucial for safety, compliance, and inventory management. Traditional methods can be time-consuming, labor-intensive, and prone to human error. Enter 3D laser scanning technology, a game-changing solution that's transforming the way we approach tank inspections and calibrations.

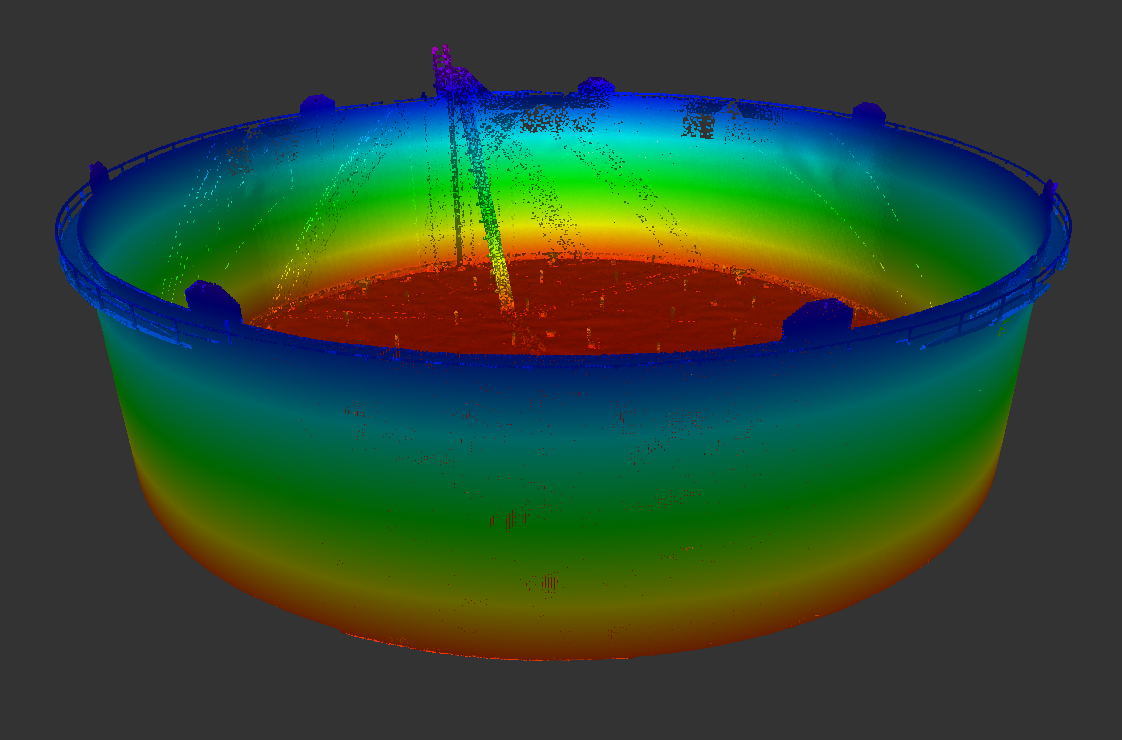

3D laser scanning uses LiDAR (Light Detection and Ranging) technology to create highly detailed, three-dimensional digital models of storage tanks. This non-contact method captures millions of data points in minutes, providing a comprehensive view of the tank's interior and exterior surfaces.

Key benefits of 3D laser scanning for tank inspection and calibration include:

The scanning process involves setting up the laser scanner at multiple positions around and inside the tank. The collected data is then processed using specialized software to create a point cloud, which can be further refined into a 3D model or 2D drawings.

For calibration purposes, the precise measurements obtained from 3D scans allow for highly accurate volume calculations. This is particularly valuable for tanks with complex geometries or those that have undergone deformation over time.

Additionally, 3D laser scanning facilitates:

As the technology continues to advance and become more accessible, 3D laser scanning is set to become the new standard in storage tank inspection and calibration, offering unparalleled accuracy, efficiency, and safety benefits to the industry